Vacuum Evaporation

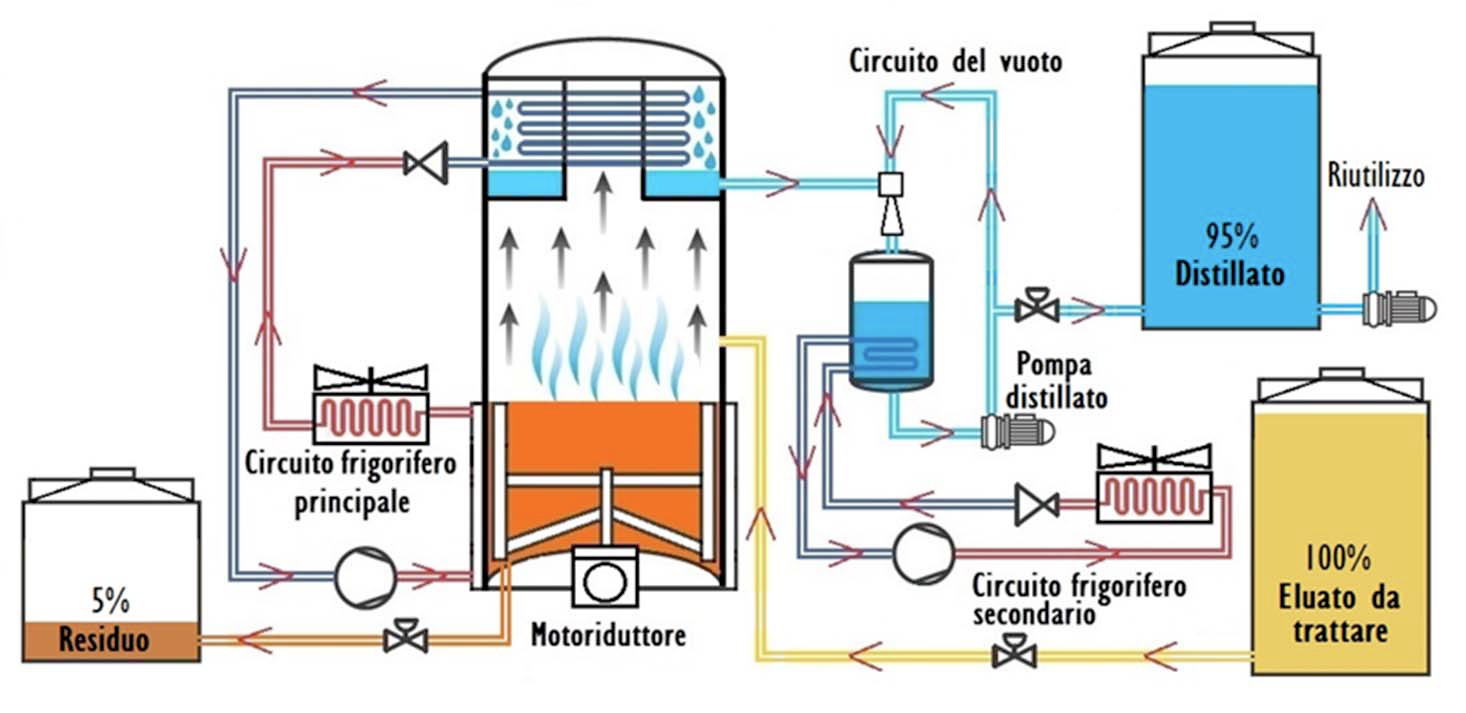

It is a thermodynamic process in which the change of state from liquid to gas is exploited, which occurs under vacuum at lower temperatures. This allows significant energy savings because low-cost energy sources can be used, thus obtaining two products:

- distilled water, which can be reused in the production cycle that produced the wastewater;

- concentrated pollutant, which can be recovered (zero discharge) to allow the recovery of precious raw materials, or sent for disposal;

all without the use of chemicals.

Vacuum evaporation plants are intended for all those production processes which, in the various processing stages, generate polluting waste or waste destined for purification.

WHY VACUUM EVAPORATION IS CONVENIENT

The use of the vacuum evaporation technique is convenient from an economic point of view because it allows a drastic reduction of disposal costs based on the pollutant content, even over 95%, allowing the recovery of diluted raw materials and significant savings on the consumption of ‘water.

The logistical aspect will also benefit from it with a considerable reduction in volumes handled and related transport.

The convenience of using vacuum evaporation systems is supported by the fact that:

- they can be integrated into existing systems;

- need a low energy intake;

- during distillation they work at low evaporation temperatures;

- they do not require supervision because they work automatically;

- they are designed for easy maintenance;

- They have excellent resistance to corrosion through the use of suitable materials

- the distillate can be reintroduced into the production cycle creating a closed-loop system (zero discharge);

- are able to obtain high degrees of concentration so the volumes of the concentrate to be disposed of are reduced by over 90%.

INSTALLATION TYPES

Each project is tailored to the treatment of products of different nature and quantity.

The choice of the evaporation plant must take into account several factors.

The nature of the product to be treated determines the choice of version (immersed exchanger, forced circulation, scraped jacket, etc.) and the choice of the most suitable construction material.

The next choice concerns the most suitable energy supply by evaluating the energy costs and the availability of low-cost heat sources present on the site.

It is possible to choose between an all-electric power supply with the application of a so-called “heat pump” system which allows for extremely simple installation, or using any flows of hot water or steam already available on site, with possibility of recovering thermal waste from the production process.

Each of these systems, electric or thermal, can be made in multiple effect versions (double or triple effect) allowing for significant energy savings.

CONSTRUCTION MATERIALS

The excellent performance and duration of the plants made is guaranteed by the use of high quality materials and components.

The choice of the most suitable construction materials is essential in the system design phase.

Starting from AISI 316 L stainless steel, for less complex corrosive applications, up to the use of materials such as DUPLEX, SUPERDUPLEX, TITANIUM, SILICON CARBIDE, GRAPHITE, and thick anticorrosive coatings based on FLUOROCARBON RESINS.

WHERE VACUUM EVAPORATION IS USED

The fields of application in which vacuum evaporation as a technique is simple and effective are many, practically all sectors where the goal is to separate water to be reused in the production process, from a solution or wastewater.

Vacuum evaporation plants are the most advanced system for the recovery of raw materials and for the treatment of liquids with a high concentration of pollutants, such as for example in the treatment of waste water from:

- METALWORKING SECTOR: wastewater from “mass-metal finishing”, washings, oily emulsions, lubricants and coolants, release agents, washings from heat treatments, pickling baths;

- GALVANIC SECTOR: recovery of copper, nickel, chromium baths, eluates from resin plant regeneration;

- FOOD SECTOR: wastewater from production and packaging lines;

- REVERSE OSMOSIS PLANTS: high density saline solutions;

- PAINTINGS: parts washing waste, phosphor chromating and cataphoresis;

- DIGESTATE FROM BIOGAS GENERATION PLANTS: wastewater from livestock farms, organic fraction from municipal solid waste;

- CHEMICAL AND PHARMACEUTICAL: wastewater from production lines, packaging and reactor washing;

- LANDFILL LEACHATE

POTENTIAL

Our evaporators can produce: from 250 to 50,000 litres/day in electric mode, from 1,200 to 100,000 litres/day in thermal mode.

UNIT DESCRIPTION

The unit is made up of two stainless steel scraped effects. The particular profile of the concentrators with scraped walls allows the achievement of a higher degree of concentration of the wastewater to be disposed of, which cannot be achieved with other evaporation techniques. The two effects operate at two different degrees of vacuum. This scheme allows for a reduction in energy consumption, as the second effect is powered by the steam produced by the first. All process parameters are indicated and regulated by field and/or digital instruments. The whole unit is managed by a PLC and does not require the continuous presence of a conductor.

DATA SHEET

- Evaporated water capacity* kg/h 200

- Daily evaporated water potential* t/d 4.8

- Electricity consumption per ton of distilled water kW/t 32

- Methane consumption per ton of distilled water Nm3/t 8.5

- Overall dimensions approx mm 4000x1600x3500H

- Plant weight approx kg 2500

* Data referred to aqueous solution with specific weight 1.0 kg/l at 25°C

SUPPLY CONDITIONS

The unit is assembled and tested at our Bolzano Vic plant. ready to be connected in your establishment and will be accompanied by an operating manual, CE certificate of conformity.

SUPPLY EXCLUSIONS

- unit installation;

- utilities (steam and cooling water)

YIELD Ex works

WARRANTY 12 (Twelve) months from delivery date;

SCRAPED DOUBLE EFFECT CONCENTRATOR MOD. WE200WR2E

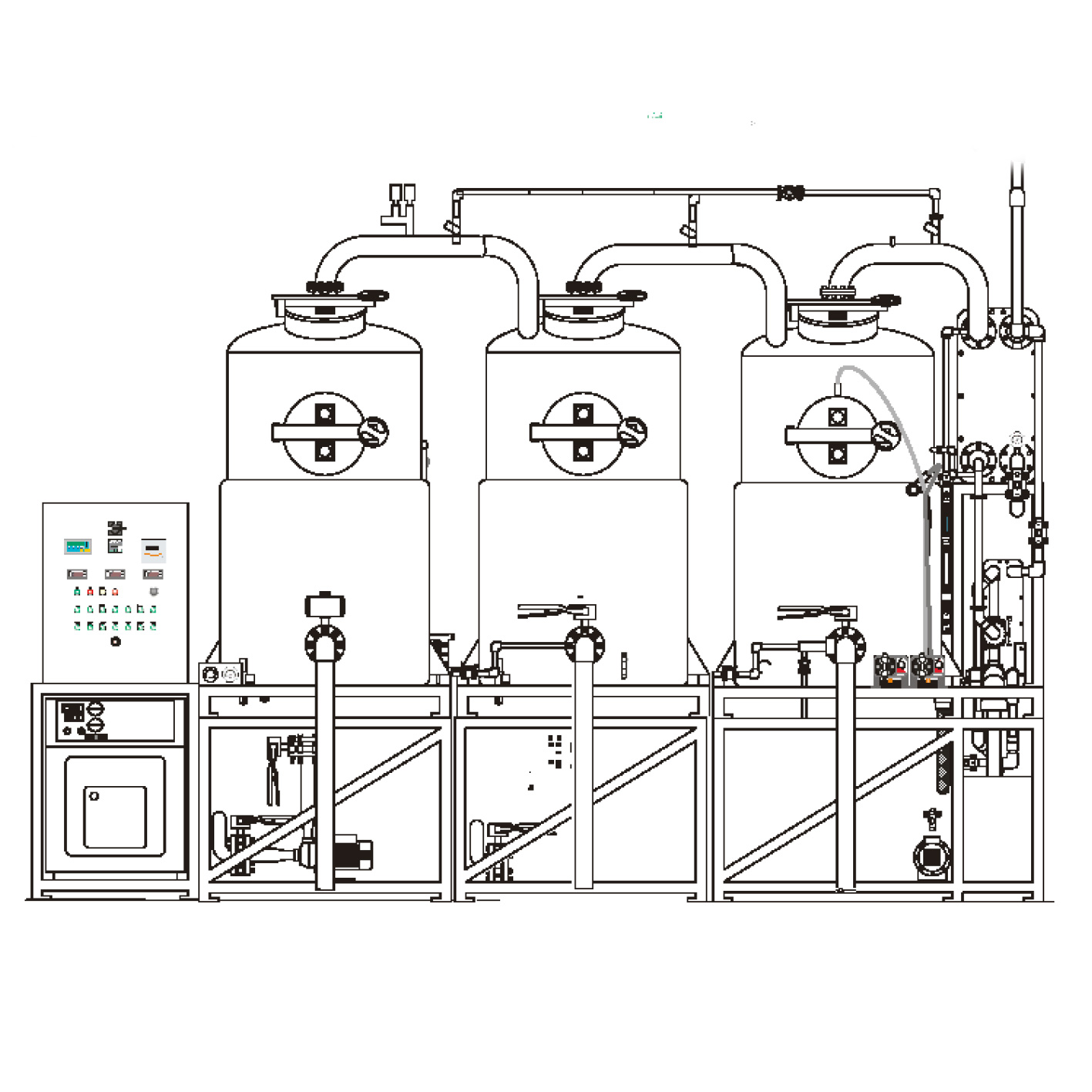

UNIT DESCRIPTION

The unit is made up of three stainless steel scraped effects. The particular profile of the concentrators with scraped walls allows the achievement of a higher degree of concentration of the wastewater to be disposed of, which cannot be achieved with other evaporation techniques. The three effects operate at three different degrees of vacuum. This scheme allows for a reduction in energy consumption, as the third effect is powered by the steam of the second effect which is powered by the steam produced by the first. All process parameters are indicated and regulated by field and/or digital instruments. The whole unit is managed by a PLC and does not require the continuous presence of a conductor.

DATA SHEET

- Evaporated water capacity* kg/h 500

- Daily evaporated water potential* t/d 12

- Electricity consumption per ton of distilled water kW/t 16

- Natural gas consumption per ton of distilled water Nm3/t 18

- Overall dimensions approx mm 6000x2000x5100H

- Plant weight approx kg 4500

* Data referred to aqueous solution with specific weight 1.0 kg/l at 25°C

SUPPLY CONDITIONS

The unit is assembled and tested at our Bolzano Vic plant. ready to be connected in your establishment and will be accompanied by an operating manual, CE certificate of conformity.

SUPPLY EXCLUSIONS

- unit installation;

- utilities (steam and cooling water)

YIELD Ex works

WARRANTY 12 (Twelve) months from delivery date;

SCRAPED TRIPLE EFFECT CONCENTRATOR MOD. WE500SR3E

UNIT DESCRIPTION

The unit in question is a continuous cycle vacuum evaporator for encrusting aqueous solutions with heat pump heating equipped with scraper with inspection porthole for complete accessibility of the appliance in case of cleaning. A control panel equipped with PLC provides for the automatic management of the system. All of this enables automatic operation without a system operator.

DATA SHEET

- Capacity of evaporated water* kg/h 52

- Electric power installed KW 15

- Electricity consumption per ton of water dist. kW/t 175

- Compressed air consumption at 6 bar Nm3/h 0.5

- Overall dimensions approx mm 500x1200x2400h

- Voltage / frequency VAC/Hz 400/50

- Weight approx 1000 kg

* Data referred to aqueous solution with specific weight 1.0 kg/l at 25°C

SUPPLY CONDITIONS

The unit is assembled and tested at our Bolzano Vic plant. ready to be connected in your establishment and will be accompanied by an operating manual, CE certificate of conformity.

SUPPLY EXCLUSIONS

- unit installation;

YIELD Ex works

WARRANTY 12 (Twelve) months from delivery date;

SCRAPED HEAT PUMP CONCENTRATOR MOD. WE50HPR